Comparing Practices in Creameries and Wineries

The FDA Food Code specifies sanitation practices in food and beverage processing facilities such as creameries.

The Food Code traces its history of the Pure Food and Drug Act of 1906. The purpose of this is to limit transmission of harmful microbes to humans in the foods we eat.

The Food Code traces its history of the Pure Food and Drug Act of 1906. The purpose of this is to limit transmission of harmful microbes to humans in the foods we eat.

The Food Code includes guidelines for facility construction, waste handling, product labeling, safe food storage, handling and preparation. The Food Code is product-specific, depending on what microbes can be harbored in the material and in the facility. For example, creameries handle raw milk, which is known to harbor dangerous microbes such as Listeria. Facility surfaces and layout, and material handling, must be designed to control microbial content in the final product. In addition, cheese requires specific microbes for fermentation that impact the organoleptic properties of the product.

The Food Code is updated every 4 years, and cites scientific literature to justify building construction and food handling practices. Our project can provide information to help facility managers understand microbial sources, vectors and reservoirs, to improve the safety of the US food supply.

One of the most well-known requirements of the Food Code is the "Wash Hands" signs you see at restaurants. These are also in food processing facilities, such as this photo taken in a winery restroom.

Winemaking Requires Only General Sanitation

Unlike creameries, wineries operate seasonally: the typical processing season is 8 weeks, called "crush", in September-October in California.

Unlike creameries, wineries operate seasonally: the typical processing season is 8 weeks, called "crush", in September-October in California.

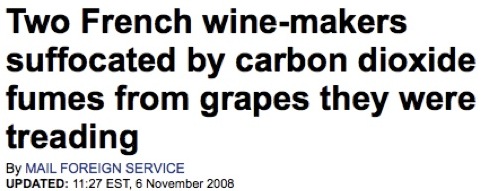

Buildings are often open to the outdoors to encourage a high level of airflow to vent high levels of carbon dioxide, a by-product of fermentation. Carbon dioxide can reach toxic levels! One liter of grape juice can generate 60 liters of CO2 gas.

Very high levels of (volatile organic compounds) (VOCs) are present from generation of alcohol. Grape musts and wines do not support growth of pathogenic organisms because fermentation produces sufficient ethanol to prevent growth of these microbes.